The HET FA-18 ARF kit is not terribly hard to assemble. However, the vertical stabs are probably the trickiest (and most annoying) part. The instructions tell you they are to be glued at 110-degree angles. But, even with a template cut at 110-degrees, it ain’t easy to immobilize those fins while the epoxy cures. Sure, you can use pins, rubber bands, tape, etc., but here’s an option that I like much better.

MAKE A GLUING JIG FOR 110-DEGREE FINS

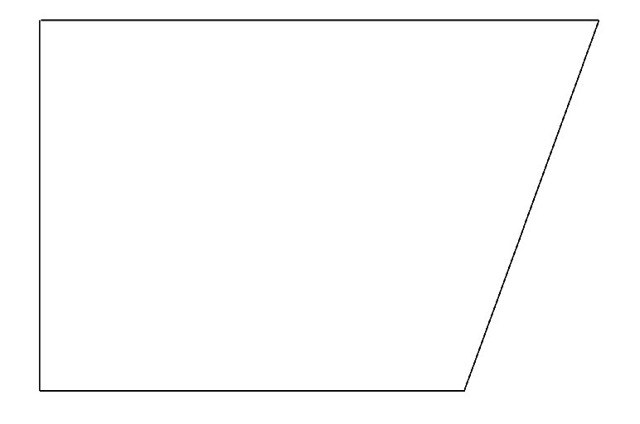

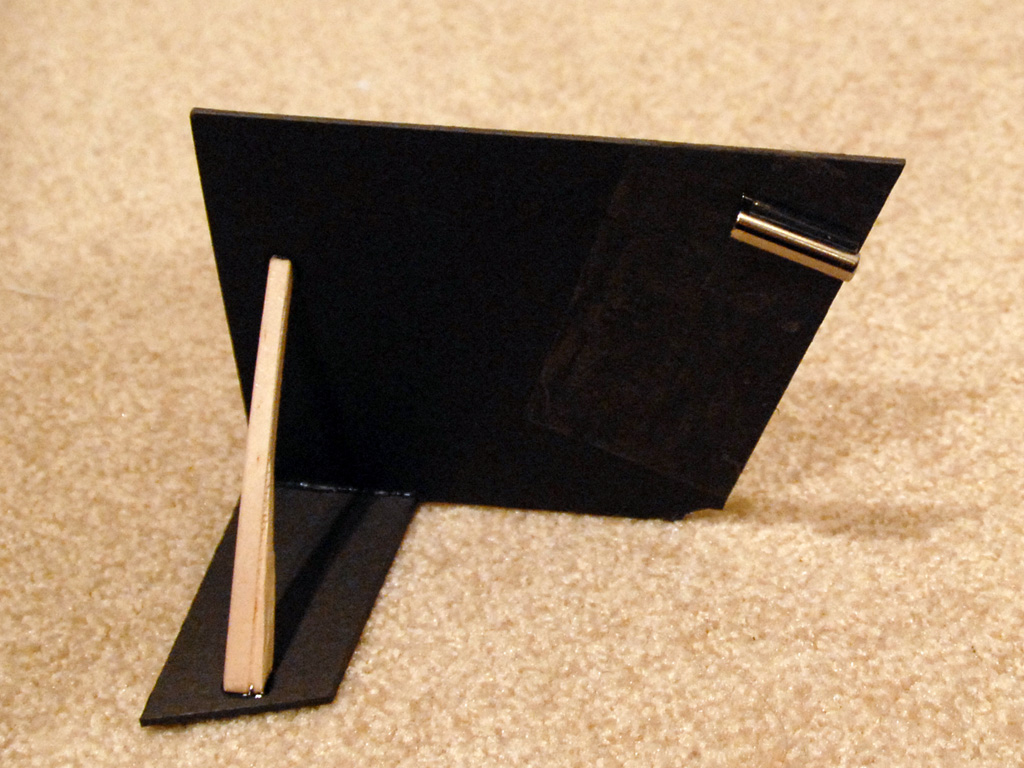

Making a simple gluing jig doesn’t take that much time and it will save you frustration when it comes to gluing the oh-so critical 110-degree vertical stabs. Here’s a photo that shows the basic idea:

Note: CLICK TO ENLARGE/REDUCE IMAGES !

This glamorized template does two things over the simple 110-degree flat template:

- Provides a horizontal footing so the vertical template can stand-up solidly.

- Uses rare earth magnets to hold the vertical stab firmly and cleanly (no pins, rubber bands, or tape!).

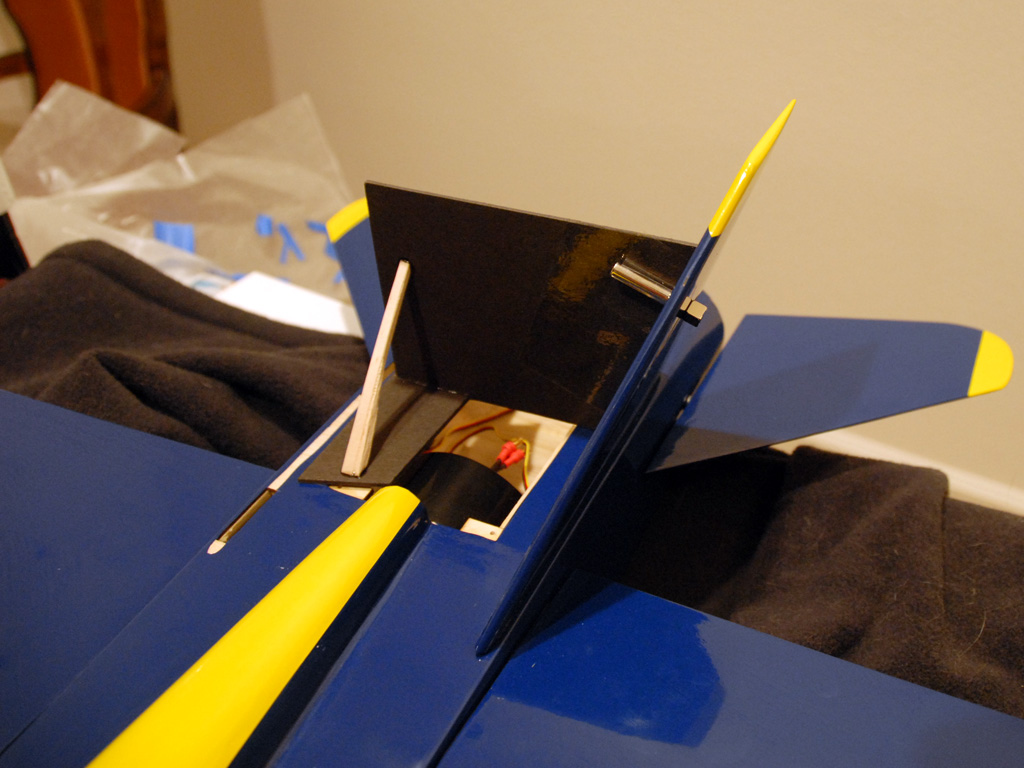

Notice there are two rare earth magnets holding the vertical stab in-place: A cylinder-shaped magnet taped to the jig and a smaller cubed-shaped one on the other side of the stab that is held in place by magnetic force. It’s like a magnet sandwich that secures the stab to the edge of the jig.

Where to get rare earth magnets: I bought an assorted pack of rare earth magnets from thinkgeek.com ("Curiously Strong Magnets") and they have been useful in many applications around the house and RC. The variety pack has several shapes and sizes. 87 pieces in all. The flat shaped magnets are great for securing a removeable canopy. Great investment for lots of uses that continually come up (love ’em!).

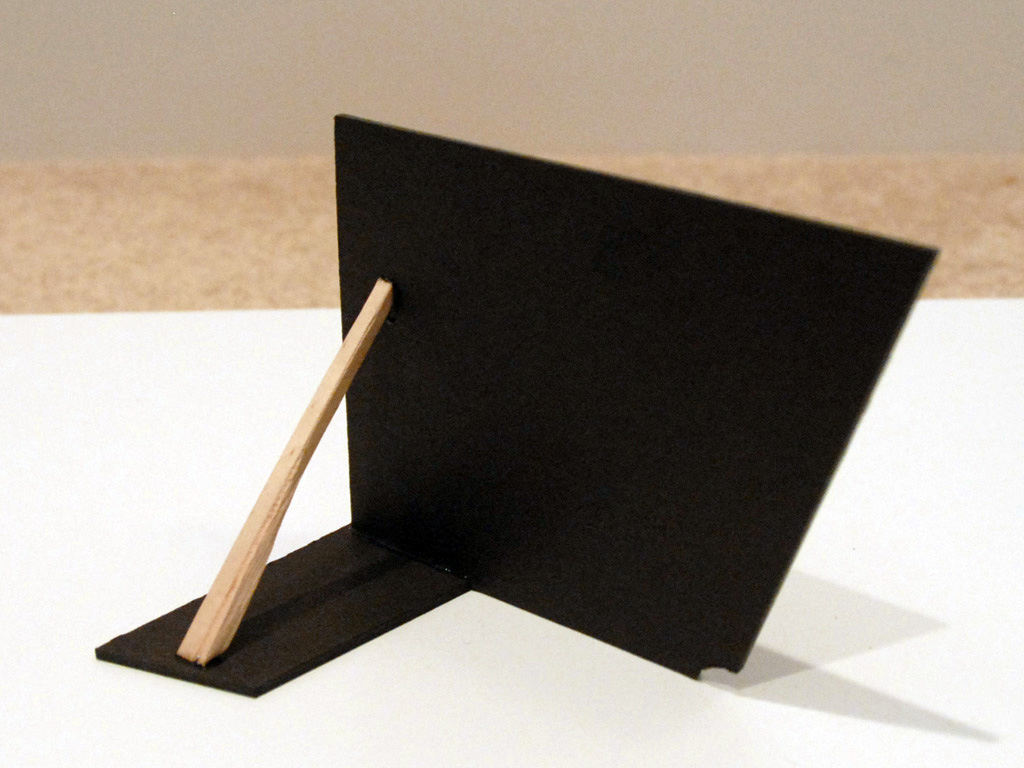

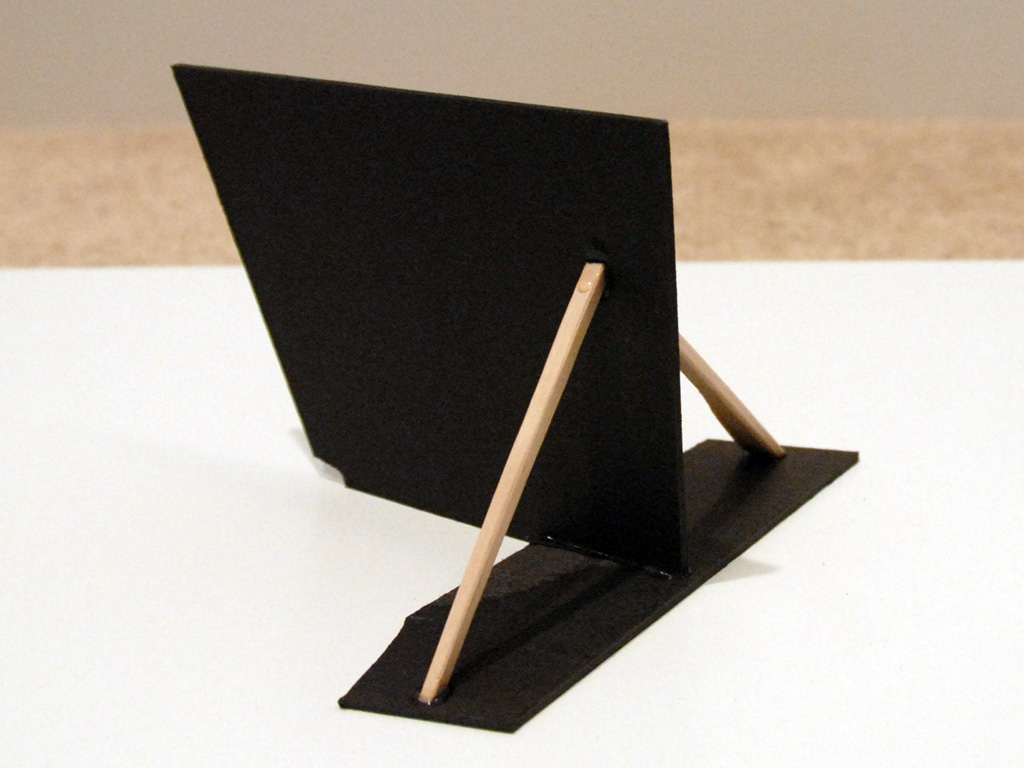

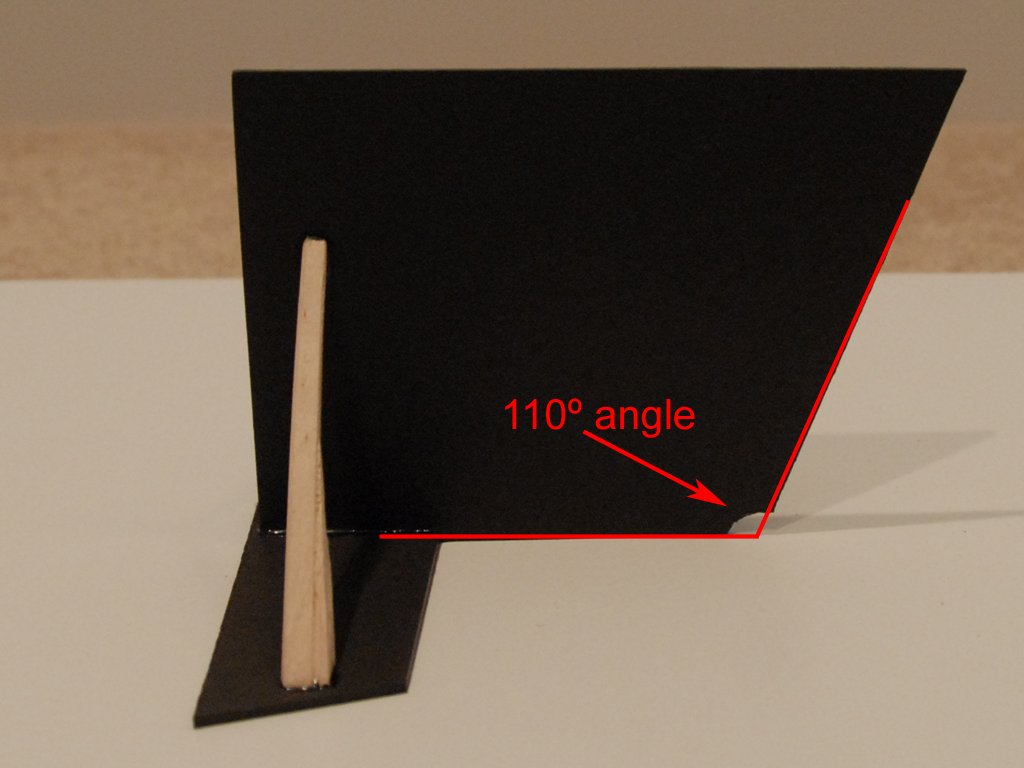

Here are more pics of the jig:

The black material is a very thick cardboard backing I found on an old memo pad (it does not flex). I just expoxied pieces of a wooden chopstick to act as support braces. You can’t see it, but there’s a long notch in the corner of the vertical piece that allows the horizontal footing to sit flush with the bottom edge of the vertical piece.

You can see in the following pic that I used a long cylinder shaped magnet and taped it to the jig with clear packing tape:

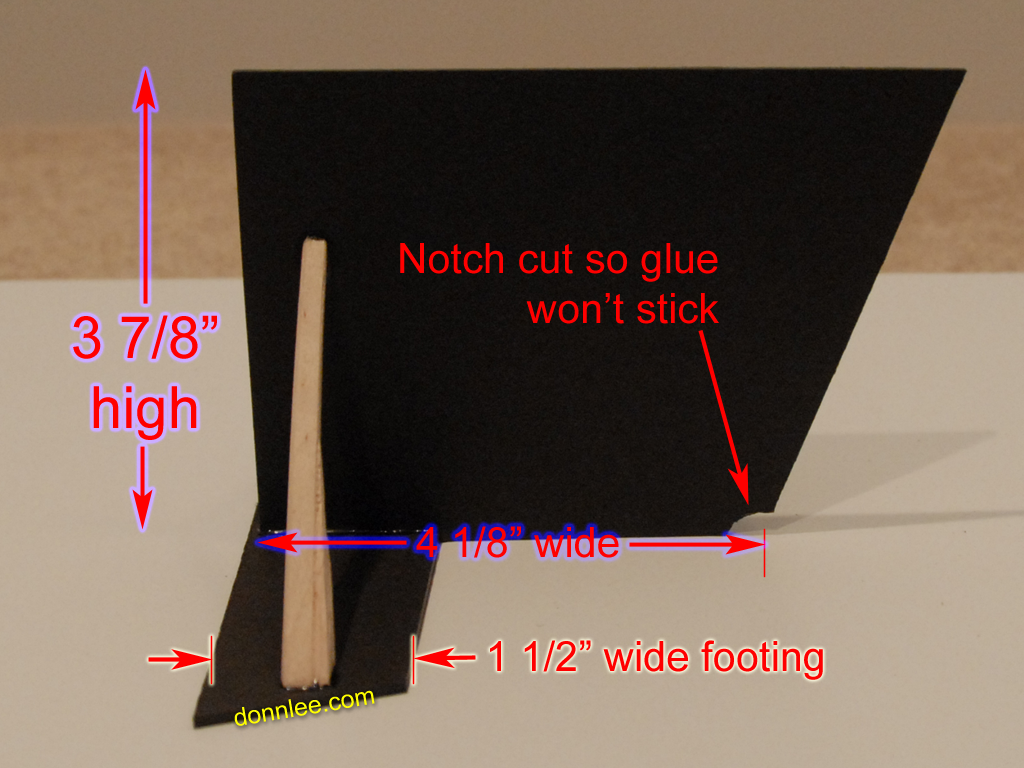

Here are the dimensions:

Note: It is important that the bottom edge of the vertical piece measure 4 and 1/8th inches. This width is narrow enough to allow you to glue the second vertical stab after the first one is done. And this width is wide enough to span the opening left by the absent rear hatch (so the jig doesn’t fall into the fan compartment).

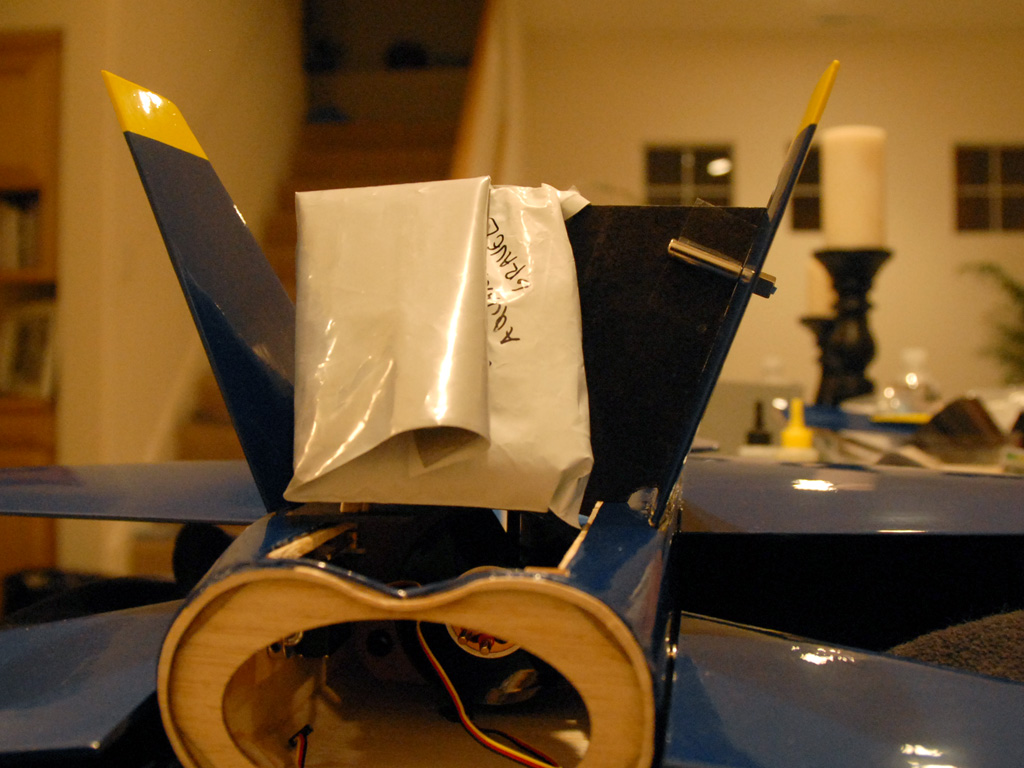

So, I place the jig over the opening, lay down the epoxy, set the stab in-place, and immobilize with the outer magnet:

Then, I anchor the jig down with a little weight. Here I used a small plastic bag of clean, dry aquarium gravel. This keeps the jig from moving around.

THAT’S SO EASY. And I know that baby is rock-solid and exactly 110-degrees for the entire epoxy curing time.

And then the other side:

A little pre-work saves hassle and errors when it counts!

See my other FA-18 tips:

- How to make a simple 65mm block-up for gluing the wings

- Using an audible countdown timer means you don’t have to take your eyes off this screamer

Enjoy!

Donn Lee

Special thanks to warbirds-rc.com for helping build and fly this great EDF jet.